© 2025 King Klinker. All rights reserved

Design and implementation: zjednoczenie

When laying clinker brick slips, it is necessary to follow the installation recommendations. This will save you time and money, and allow you to enjoy your aesthetic façade for many years to come.

The walls on which brick slips and fittings are laid should be even, solid and dry. Do not affix brick slips to damp plaster. Bonding and settlement processes should also be completed in the substrate. The surface of the substrate prepared for bonding should not be smooth; to increase adhesion, you may scratch it with a sharp tool and prime it.

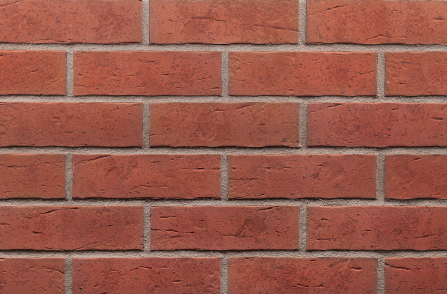

Differences in shades are a natural feature of clinker resulting from the manufacturing process. They make the surface covered with a clinker to look very natural. However, to obtain this effect, it has to be remembered to mix brick slips from different packages. It’s recommended to lay out a pattern of dry-mixed brick slips on a horizontal surface before assembling them to the wall. It is also advisable to purchase the goods from the same batch. The clinker purchased 6 or 12 months later, may differ in shade from the previous ones.

When laying clinker products, use adhesive mortars designed for this purpose. Frost-resistant mortars should be used outdoors. The adhesive mortar should be flexible and adapted to the absorbability of the brick slips. When laying brick slips, always follow all the adhesive manufacturer’s recommendations listed on the adhesive packaging. The maximum thickness of the adhesive should be no more than 5 mm. The adhesive should fill 100% of the entire installation surface of the tile in contact with the wall.

Joints should be left between the brick slips. Keeping in mind the natural curvature of the brick slips due to the characteristics of ceramic products, we recommend a joint width of 10-12 mm. The joints should always be filled with mortars designed for pointing clinker brick slips. Mortars in the joints should be flush with the front of the cladding and given a slightly concave profile. On the façade, the clinker cladding should line up vertically with the plaster on the wall. If the cladding juts out above the render, it must be protected against water intrusion. Semi-dry pointing is recommended. Sludging is not advisable. Impregnation of products is not recommended.

The surface made of thin bricks should be dry brushed and washed with warm water.

Only in particularly difficult cases, use cleaning agents, following the manufacturer’s recommendations with particular care.

Thin bricks may not be cleaned with acids.

Plastic or metal mesh is used, most often fixed to the insulation layer with wall studs. A layer of thin-bed mortar is applied on top of it and then dried. Subsequently, a second layer of thin-bed adhesive is applied and the clinker brick slips are adhered ensuring that there are no voids between the brick slips and the adhesive surface. Once the brick slips have bonded to the wall surface, semi-dry pointing can be carried out.

Arranged in special moulds with the outer surface (face) inwards, the waxed clinker brick slips are poured in concrete, based on a specific design of a larger façade component intended for a specific building. Once dry, the finished components are assembled on site and the wax layer is removed with pressurised water. This method is used in structures built by lifting components from a horizontal position (tilt-up) and in precast plants. It significantly reduces costs and time on site, delivering an extremely precise building façade that will last for centuries.

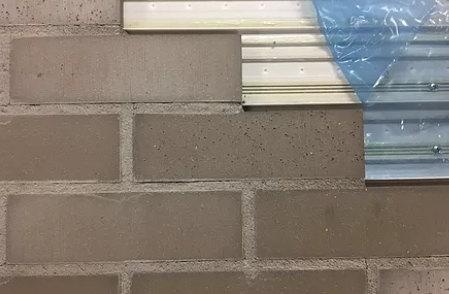

A cement board, with façade brick slips attached to it, is prepared in advance at the precast plant. The ready-made boards are mounted (screwed) in modules to the façade. This gives the opportunity to design a clinker façade without the cost of substrate preparation. This method significantly reduces the labour costs associated with gluing brick slips or bricklaying.

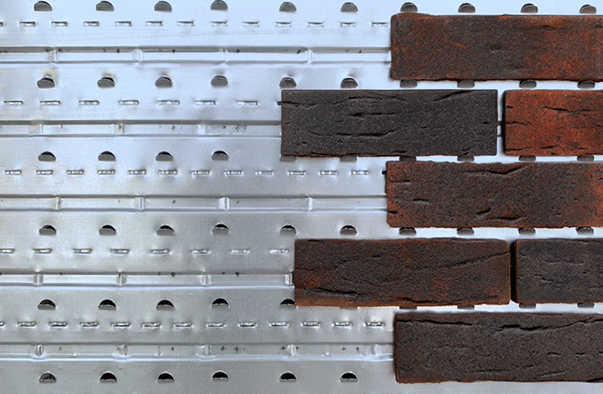

Metal panel systems with façade brick slips provide flexibility in design, eliminating the cost of substrate preparation, and can be used with less stable or lighter building wall structures. This system is usually installed together with the drainage layers, as water can penetrate through the panels and wash out the substrate.

The Speedymason system is the only one in this category that allows a full set of thin-bed mortar to be used between the panel and the façade tile. It includes markings showing where to place the façade tile, making it easier to lay. This system features the simplicity of the traditional method, and by streamlining it saves time and reduces labour costs.

This method is for interiors only. It is a patented composite panel made exclusively by Speedymason, which can be attached directly to plasterboard or any other surface. The panel has an adhesive layer applied. Once the protective film has been peeled off, simply press down the brick slips and apply pointing. This is the quickest and easiest clinker tile installation method available.

In the case of brick and clinker tile façades, semi-dry pointing is the only method that guarantees the best aesthetic appearance of the façade. Please take a look at the video.

watch video

watch video

watch video

watch video