© 2025 King Klinker. All rights reserved

Design and implementation: zjednoczenie

KING KLINKER products are manufactured using traditional method of drawing from plastic ceramic mass, which is a mixture of the highest quality clays. After the ceramic mass has been properly ground and homogenised, the products undergo the extrusion moulding process. Moulding is done wet with respect for traditional methods. After being moulded, the façade brick slips undergo a drying process followed by firing at temperatures exceeding 1000°C. The production method we use guarantees weather resistance, longevity and colour fastness.

The applicable regulations and standards set minimum parameters that all clinker products placed on the market must comply with. KING KLINKER products significantly exceed the requirements specified by the standards. Bending strength is twice as high as required and water absorption is maintained at around 3%. The frost resistance of our brick slips is 10 times higher than the standard requirements.

During use, KING KLINKER products do not release any harmful substances, which is why they are used both on façades and inside buildings. We use only natural raw materials in production. In addition, all production waste including clay-contaminated water is 100% reused in the production process.

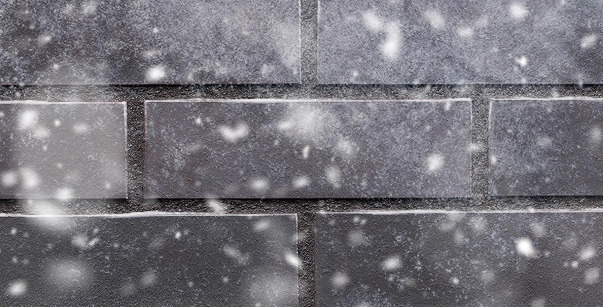

Thanks to low absorbability, the tiles are weatherproof and perform well in areas exposed to higher levels of moisture.

| Absorbability according to EN ISO 10545-3 | |

|---|---|

| for red and brown mass brick slip | ~ 3% |

| for white and yellow clay brick slip | < 6% |

Frost resistance according to EN ISO 10545-12 – meets criteria

After being soaked in water, the brick slip are subjected to a minimum of 100 freeze-thaw cycles at temperatures between -5/+5°C. A test carried out by the Institute of Ceramics and Building Materials demonstrated the absence of any damage after 1,000 cycles (10 times the standard).

Downloads: frost resistance test performed by

Institute of Ceramics and Building Materials

Full frost resistance certificate 1000 cycles without damage

Minimum 10 times above the standard

Reaction to fire class according to EN 13501 – A1

Non-flammable material – does not contribute to the development of fire. Even under developed fire conditions (800°C), it does not ignite (does not emit heat, smoke or flaming droplets or particles).

Bending strength according to EN 10545-4 – above 13 N/mm2

The test consists of determining the bending strength of the entire tile by applying a force of a certain magnitude at a certain distance from the centre of the tile.

Breaking force according to EN ISO 10545-4 – above 800 N

The test consists of determining the breaking load and breaking force by applying a force of a certain magnitude at a certain distance from the centre of the tile.

KING KLINKER products meet the dimensional and surface quality requirements specified in

EN 14411 Annex C, Requirements for – Natural.

| Length and width | Permissible deviation of the average dimension of each tile (2 or 4 sides) from the working dimension is ±2.0%, maximum ±4 mm |

| Thickness | Permissible deviation in percentage of the average thickness of each tile from the working thickness is ±10% |

| Curvature of sides (facing surface) | Maximum permissible deviation from a straight line, in percentage in relation to the relevant working dimensions, is ±1.0% |

| Deviation from right angle | Maximum permissible deviation from right angle, in percentage in relation to the relevant working dimensions, is ±1.0% |

| Surface flatness | Deformation with respect to the diagonal calculated from the working dimensions is ±1.5% Curvature of the sides in relation to the relevant working dimension is ±1.5% |